This site uses cookies to provide an optimized shopping experience. By using this site, you agree the use of cookies within our privacy policy.

Product Catalog

-

Test and Measurement Equipment Show More

Test and Measurement Equipment Show More -

HVAC-R Tools and Supplies Show More

HVAC-R Tools and Supplies Show More -

Datacom and Network Test Show More

Datacom and Network Test Show More -

Soldering and Desoldering Show More

Soldering and Desoldering Show More -

Static-ESD Control Show More

Static-ESD Control Show More -

Instrumentation and Lab Equipment Show More

Instrumentation and Lab Equipment Show More -

Hand and Power Tools Show More

Hand and Power Tools Show More -

Wire and Cable Management Show More

Wire and Cable Management Show More -

Inspection Tools, Lights, Magnifiers, and Microscopes Show More

Inspection Tools, Lights, Magnifiers, and Microscopes Show More -

Broadcast and Video Show More

Broadcast and Video Show More -

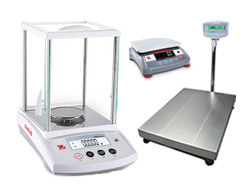

Scales and Balances Show More

Scales and Balances Show More -

Electronic Kits and Toys Show More

Electronic Kits and Toys Show More -

Drain Maintenance Show More

Drain Maintenance Show More -

Accessories Show More

Accessories Show More -

Depot Deals Show More

Depot Deals Show More